Powerful. Safe. Effective.

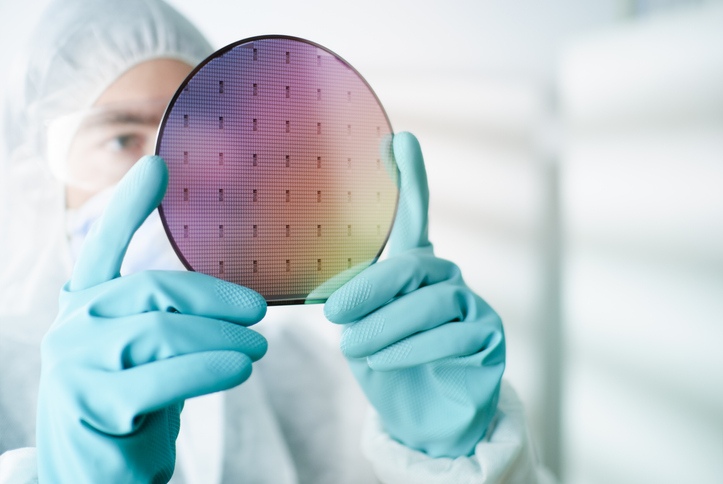

Photoresist Stripping

Dimethyl Sulfoxide has several functions in the electronics industry. DMSO exhibits excellent solubility for polymers typically used in microelectronic manufacturing as a complement to existing and common process of record (POR) solvents. The addition of DMSO as a cosolvent to an existing chemistry also improves solvency of polymers, while exhibiting excellent chemical stability.

DMSO EL-10 Grade contains extremely low metals content and is widely recognized as the DMSO of choice for microelectronic applications where low metals content is critical.

Contact Gaylord Chemical Request A Sample

Proven uses include:

- IC / TFT-LCD resist stripping applications

- Wafer level packaging PR strip

- FEOL Cu post etch clean

- TSV cleans

- Wafer bonding adhesive removal

- MEMs PR strip

The Standard in Safer Use Solvents:

- Excellent safe alternative to more hazardous polar aprotic solvents such as NMP

- Completely miscible in water

- Naturally biodegradable

- Essentially odorless

- Manufactured in the USA

Proven Safety and Performance

Photoresist Stripping

TFT-LCD Manufacturing

In the photolithographic process used to pattern thin film transistors, DMSO is combined with ethanolamine and used as a powerful remover of bulk photoresist. Pure DMSO is also used in many fabrication shops as a rinse solvent, a thinner (for edge cleaning), and in the rework of color filters.

Semiconductor Devices

DMSO is used as a major component in bulk photoresist stripping formulations, and as an additive in specialized post-etch cleaning products and edge bead removers.

Solder Bump Patterning

As an alternative to wire bonding, a final wafer processing step produces solder bumps on the surface of a chip pad. DMSO is a useful component of stripping formulations needed to strip the photoresist which patterns the solder bumps in Flip Chip packaging technology.

Learn More – Applications Testing Data

Technical Service and Consultation

Gaylord Chemical provides application specific technical service in support of all of our product grades. From formulation development and regulatory consultation to Engineering and Design consultation, we’re here to help.