Methods and Techniques

Dimethyl sulfoxide (DMSO) is a hygroscopic material. Many applications, however, require virtually anhydrous DMSO for optimum results. Some examples of such applications include organometallic reactions as well as those involving carbanion intermediates. This bulletin describes some important methods of drying DMSO and techniques for assaying water levels of dried material.

Analysis for Water in DMSO

Gas Chromatographic Method. The amount of water in DMSO can be determined by gas chromatography using a packed column (15 x 0.25” column packed with Poropak S, 50-100 mesh), with a helium flow of 50 ml/min. The method uses an isothermal temperature program (190°C) with an injector temperature of 170°C. Thermoconductivity detection (TCD) at 220°C. is employed. A sample size of 30 microliters gives sufficient peak height without too much background. Water shows up immediately after the gases absorbed in DMSO. The gas chromatograph will indicate less than 20 ppm water (0.002%) in DMSO.

DMSO has such a strong affinity for water that error is induced by pickup of moisture at the open end of a syringe needle during transfer of a sample from a serum bottle to the sample port of the instrument. The sample can be protected by enclosing the bottle containing DMSO and the sample port of the gas chromatograph in a drybox.

In another method, a sample is withdrawn through the bottle cover and a sleeve formed by a small rubber stopper. This involves first piercing the stopper with the syringe needle then the serum bottle cover. After the sample is taken, the needle is withdrawn into the stopper. The DMSO sample is injected into the chromatograph by holding the stopper tightly against the rubber septum of the injector. Methods for drying DMSO:

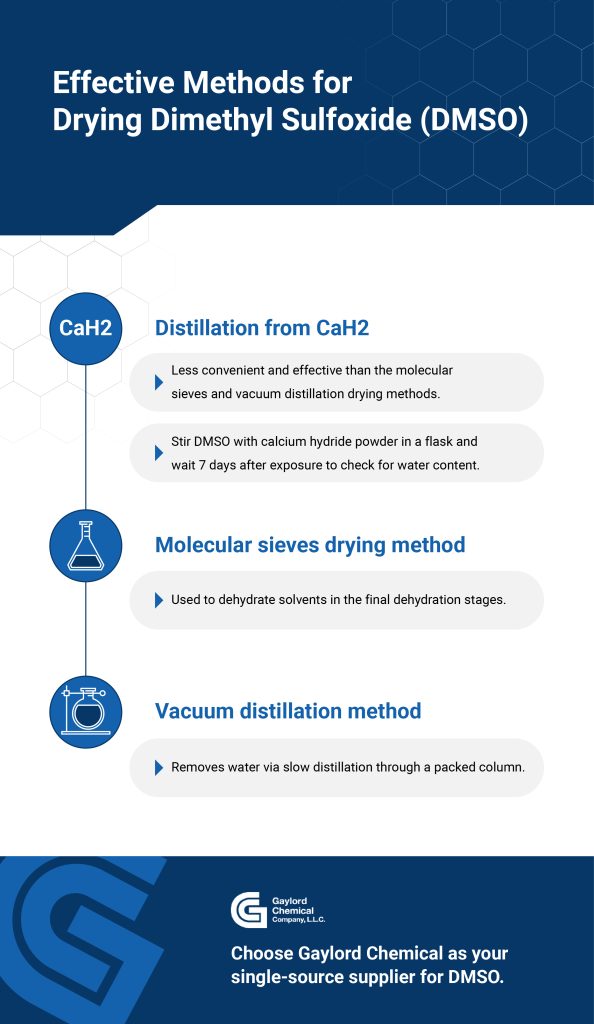

- Vacuum Distillation Method. A convenient method of preparing nearly anhydrous DMSO is to add approximately 20% excess DMSO to the reaction vessel and remove the excess and water by slow distillation through a packed column under vacuum. Removal of a 50 ml forerun from a 250 ml sample at high reflux ratio should give residual DMSO containing less than 20 ppm (0.002%) water. To distill this nearly anhydrous DMSO, non-jointed, all-glass equipment is required. A phosphorus pentoxide drying tube between the flask and pump is essential. The distilled DMSO will contain about 20 ppm water. All dried DMSO should be handled or transferred in a dry box. For the majority of applications, removal of most of the water as a distillation forerun is adequate. It is convenient and requires no special equipment. For cases where very dry DMSO is needed, the next method gives a product with negligible water content.

- Molecular Sieves Drying Method. DMSO can be dried to 10 ppm water or less using Linde molecular sieves. A glass column (5’ x1” ID )was packed with one pound molecular sieves (4Å, 14 x 30 mesh). It was activated by heating 16 hours at 325°C, with an argon flow of 6-7 ft3/hr. Thirty liters of DMSO with 270 ppm (0.027%) water were passed through this column. At the mid-point, the DMSO may contain 6-10 ppm water. The second half may contain 15-30 ppm. Column regeneration requires washing the column first with DMSO containing 10% water, then 50% DMSO -50% water and finally with water. An extreme heat buildup results from an initial water wash due to heat of solution of DMSO. Repeat the activation step described above after the wash.

-

Distillation from CaH2: Distillation from calcium hydride has been widely used in literature reports. However, this procedure has been found to be less effective and less convenient than the first two methods described above. Typically, calcium hydride powder is stirred with DMSO in a flask vented through a phosphorus pentoxide tube. After 18 hours, the distillate (bp 4 mm Hg, 64°C) may contain 90 ppm water. After 7 days exposure, the distillate may still contain 25 ppm water.

The information in this bulletin is based on information available to us and on our observations and experiences. However, no warranty is expressed or implied regarding the accuracy of this data, the results to be obtained from the use thereof, or that any use will not infringe any patent. Each user must establish appropriate procedures for off-loading, handling, and use of the product(s). Since conditions for use are beyond our control, we will make no guarantee of results, and assume no liability for damages incurred by off-loading, handling, or use of the product(s). Nothing herein constitutes permission, or recommendation to practice any invention covered by any patent without license from the owner of the patent.